[PRO BLOG] Guide for architects and builders: Technical wind load requirements for balcony glazing

It has been predicted that by 2050, two-thirds of the world’s population will live in cities. This also creates more demand for urbanization, bringing forth a need for high-rise building. Increasing the height of the building, however, brings challenges to construction. The architect must find a solution suitable for the building in terms of aesthetics and technical performance which is safe and economically viable.

Considerations for wind load

One crucial technical element of consideration for high-rises is wind load. The wind pressure in different parts of the building must carefully be determined to ensure technical compatibility of the chosen balcony design. With tall buildings, wind pressure is particularly intense and therefore crucial to consider in all phases of the planning process.

Settlements for wind load determinations at Lumon are done through:

- Wind pressure calculations

- Wind tunnel tests

- 3D simulations

The site’s structural designer can usually find ready-made calculations on wind pressures if a new building is in question. Horizontal wind loads have a great effect on taller buildings, because the higher the building, the less it is sheltered by surrounding buildings or nature. The wind load on the building is also affected by its height, shape, and direction.

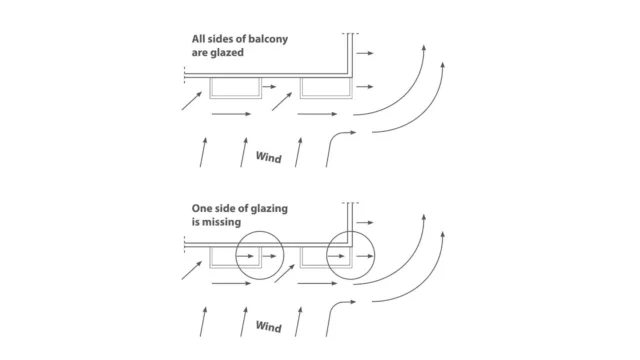

Balcony glazing should be uniform. If, for example, one side of the balcony is left unglazed, wind pressure and

suction are applied to the opposite side at the same time.

When the wind blows against the side of the building, low-pressure vortices are also created, which can ‘suck’ the glass outwards. These wind forces determine the span and thickness used in glazing – a high wind load usually requires thicker glass and/or a short span.

“The wind pressure directed at structural components is affected by the surrounding terrain, altitude, shape of building, and the location of the site in question,” notes PhD of Civil Engineering Kimmo Hilliaho in his Finnish publication RIL 272-2019 Parveke- ja terassilasitus rakennusosana – määräykset, ohjeet ja toimivat käytännöt (RIL 272 – 2019 Balcony- and terrace glazing as a building component – specifications, instructions and best practices).

Engineering features that enable wind resistance

Materials are in a central role with ensuring wind resistance. High-rise projects require materials that are robust enough to withstand strong winds, yet refined enough to complement modern architecture:

- High-grade aluminum: Lumon uses high-grade aluminum profiles that are both lightweight and strong, providing essential support without excessive bulk.

- Tempered glass: Lumon’s glazing uses single glazed tempered glass, which is highly durable and can withstand high-pressure conditions. Tempered glass is 4-6 times stronger than annealed glass. Glass thickness can be customized based on project requirements, with options ranging from 8 mm to 12 mm for added safety.

- Additional processes like heat soaking are also applied to reinforce the glass, adding an extra layer of reliability for high-rise applications. Heat-soaked glass is stronger and safer, making it an excellent choice for balconies exposed to wind loads. Our glazing has undergone numerous quality testing to ensure it can withstand 300km/h winds.

Openings in the balcony façade

Openings in the balcony facade increase the wind loads on the structures. For example, the dynamic wind pressure caused by gusts can be reduced by closing the openings on the exterior facade. In other words, the balcony glazing should be uniform. For example, if one side of the balcony is left unglazed, wind pressure and suction are applied to the opposite side at the same time.

Making informed decisions

When planning balcony glazing and considering wind load calculations, Lumon’s designing tools and project managers can help to make an informed decision for a viable solution. Depending on the wind load direction, it is also possible to have Lumon Glazing only for certain portions of the building.

Glass size and shape

Current architectural trends favour large glass surfaces, but for tall buildings, certain limitations must be considered. In tall glass elements, the strength of the glass and the deflections of the glass element often become limiting factors. The most suitable solutions are those that use a glass railing installed on top of a handrail.

Design planning

Design planning is vital for smooth logistics. It’s best to have Lumon involved from the designing stage to make sure your tall building is optimizing the benefits of Lumon Glazing, while also taking into account safety and quality issues. The earlier that Lumon can be involved to provide recommendations on how Lumon products can help to achieve a design vision, the better. Lumon’s project managers are specially trained to encourage efficient and cost-effective solutions which consider all necessary technical specifications.

Read other recent items

-

[NEWS] Lumon publishes Annual Review: Strengthening the foundation for the future

Read more…Lumon Group has published its Annual Review 2024, showcasing a year marked by resilience, strategic investments, and a strong commitment to sustainability.

-

[NEWS] Glazed balconies on the rise in Poland: Lumon strengthens presence with standout residential projects

Read more…Balcony glazing is fast becoming a hallmark of modern Polish residential architecture. Two years after establishing its subsidiary in Poland, Lumon – a global leader in frameless balcony glazing solutions – has successfully completed several high-profile residential projects, transforming urban living in cities like Warsaw, Łódź, and Pruszków.

-

Wooden buildings and glazed balconies: A perfect blend of design and sustainability

Read more…The architectural landscape is evolving, with sustainability and innovative design at the forefront. Wooden buildings, coupled with glazed balconies, offer a unique blend of natural materials and modern aesthetics. For the construction industry, this combination presents an exciting opportunity to create stylish, energy-efficient spaces that meet the growing demand for sustainable building solutions.